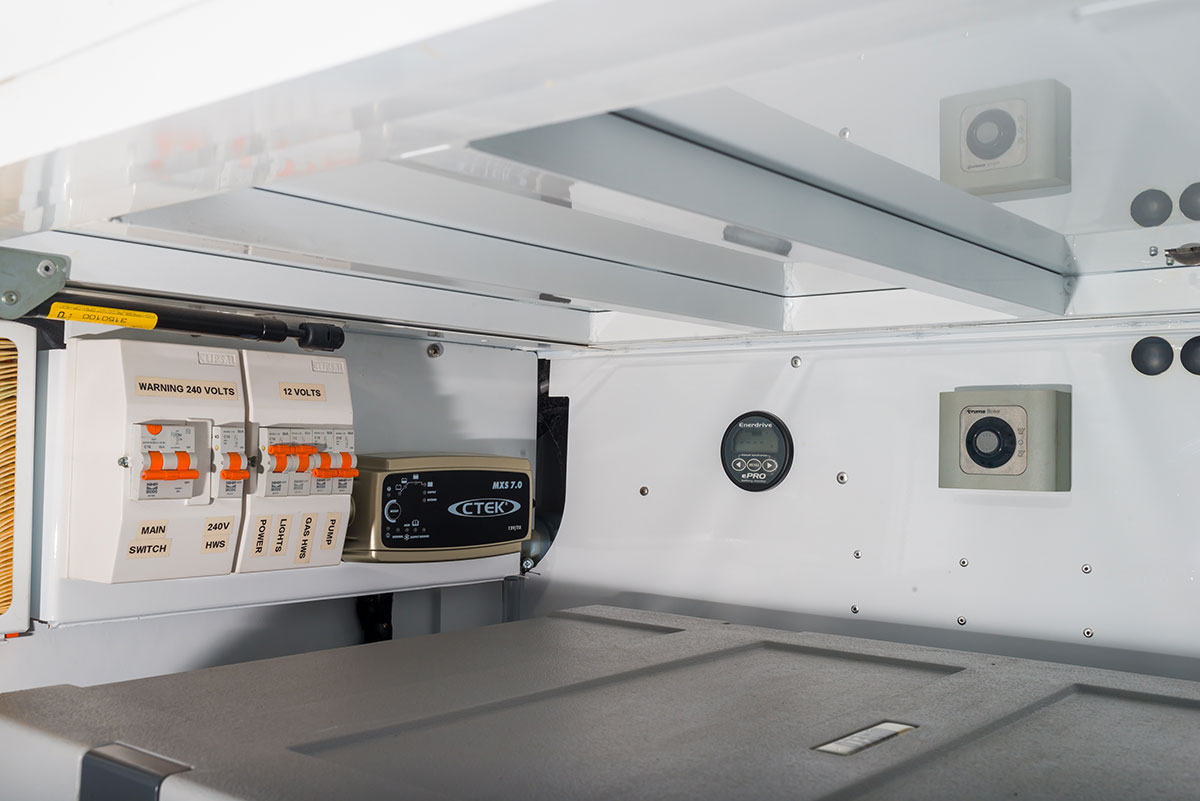

Just about all recreational vehicles these days have two separate electrical systems, one being for 240V AC mains power and the other being 12V DC battery power. They are of course connected electrically via batteries, chargers and inverters but for purposes of this article, I’ll regard them as two discrete systems.

For a very good reason I’d like to point out, mostly to do with the fact that whilst 12V systems are for the most part quite safe for the average handyman to work on, 240V mains power is a different matter entirely and a mistake could potentially kill someone.

240V MAINS POWER

For that reason, all 240V systems are legally required to be installed and/or worked on by a licensed electrician to the requirements of AS/NZS 3000 & 3001 – both electrical standards. There’s another standard AS/NZS 5033, a little less well known but which applies to the installation of solar panel systems.

All mains electrical work in a RV must be signed off by a licensed person. There is an odd exception to this in Victoria where it’s not a legal requirement for that to occur but a number of Victorian-based caravan manufacturers still used licensed persons anyway – a good thing in my opinion.

Whilst there apparently isn’t any work that can be done on 240V systems, there are still some basic checks that anyone can do. Indeed something that kills more people, electrically speaking, than just about anything else is the humble extension cord, something that just about all RVers use frequently. Regular checks on the insulation cable itself, along with both plug and socket are quite a easy check to do. Things to watch out for are damage to the cable insulation and any melting or head damage around the plug and socket. A “Tag and Test” done by an authorised person is always a good idea. Similarly powerpoints can be checked for overheating issues (usually an obvious discolouration) – most caused by high current devices like electric kettles.

A nice simple job that many DIYers get tempted into is changing an RV powerpoint. Not hard except that many don’t realise that all caravan powerpoints should be double pole (that is switched on both active and neutral). Double pole powerpoints are more expensive than the single pole models and not always readily available from your favourite hardware store.

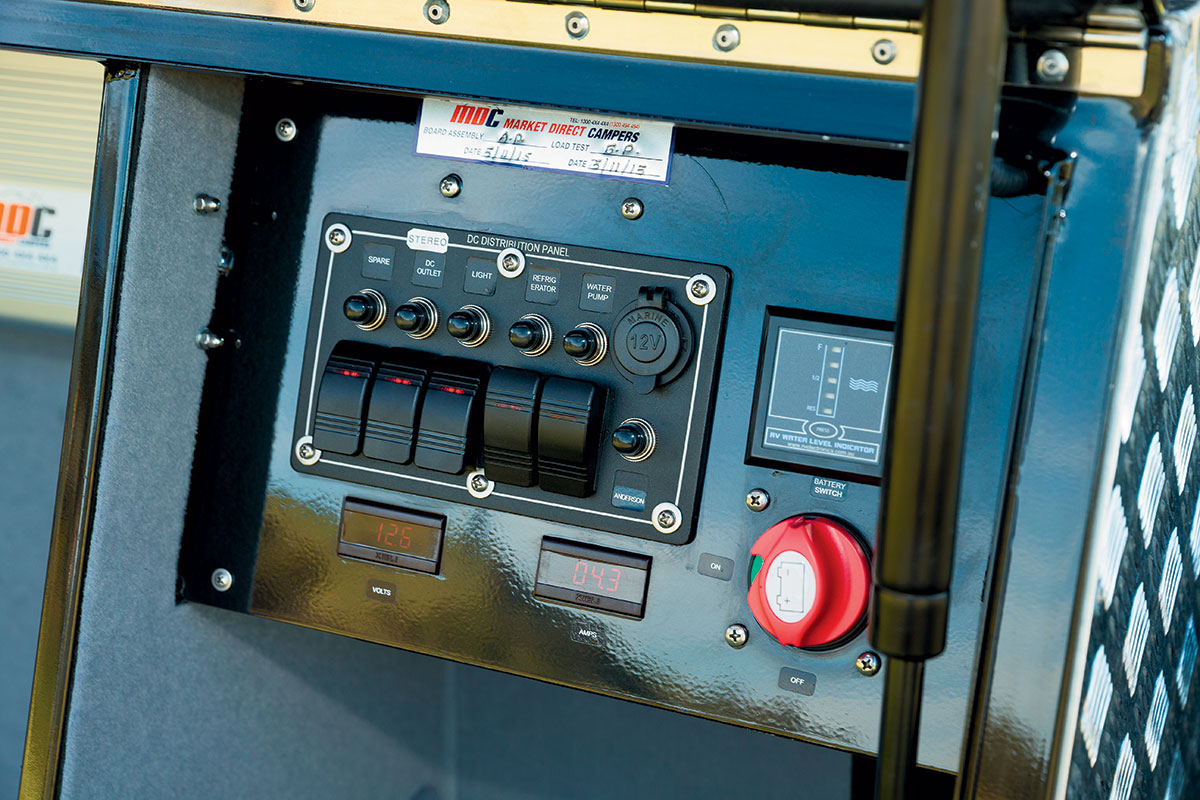

12V SYSTEMS

12V power in RVs is becoming increasingly complex but there are no applicable standards, so anyone who knows what they are doing can work on them. Just a little caveat here, knowing what you are doing is important. Many 12V devices are becoming increasingly complex and consequently expensive. Not to be too dramatic, a mistake could cause a fire at worst but more likely might hurt the bank balance and the pride.

There are also issues with using under-sized cable, which can cause voltage drop problems (i.e. by automotive cable often being sized by the diameter of the insulation, not the electrical conductor). Tools required for basic 12V work are nothing more complex than a good set of pliers, side cutters, wire strippers and a variety of parallel-tipped and Phillips head screwdrivers. Also very handy, particular for checking voltage levels is an analogue or digital multimeter. For getting into awkward locations, both bent and straight long-nose pliers are a good investment.

There are a number of caveats when working with electrical systems but particularly with mains 240V, the safest one is if in doubt, then don’t!

MEET THE AUTHOR

Malcolm Street

Malcolm Street began caravanning in the early 1970s, first in a Viscount and later in a York, the former towed by a Holden Kingswood. Malcolm has RV’d extensively across Australia, New Zealand and Britain. He became an RV journalist in 1999. Each year, he reviews around 40 caravans and motorhomes in Oz and NZ. Yes, he’s a well-travelled bloke with no shortage of campfire opinions about how a given caravan could be better put together.